Filter Press MPS – Manual Filter Press

Home » Products » Filterpresses » Filtropresse manuali

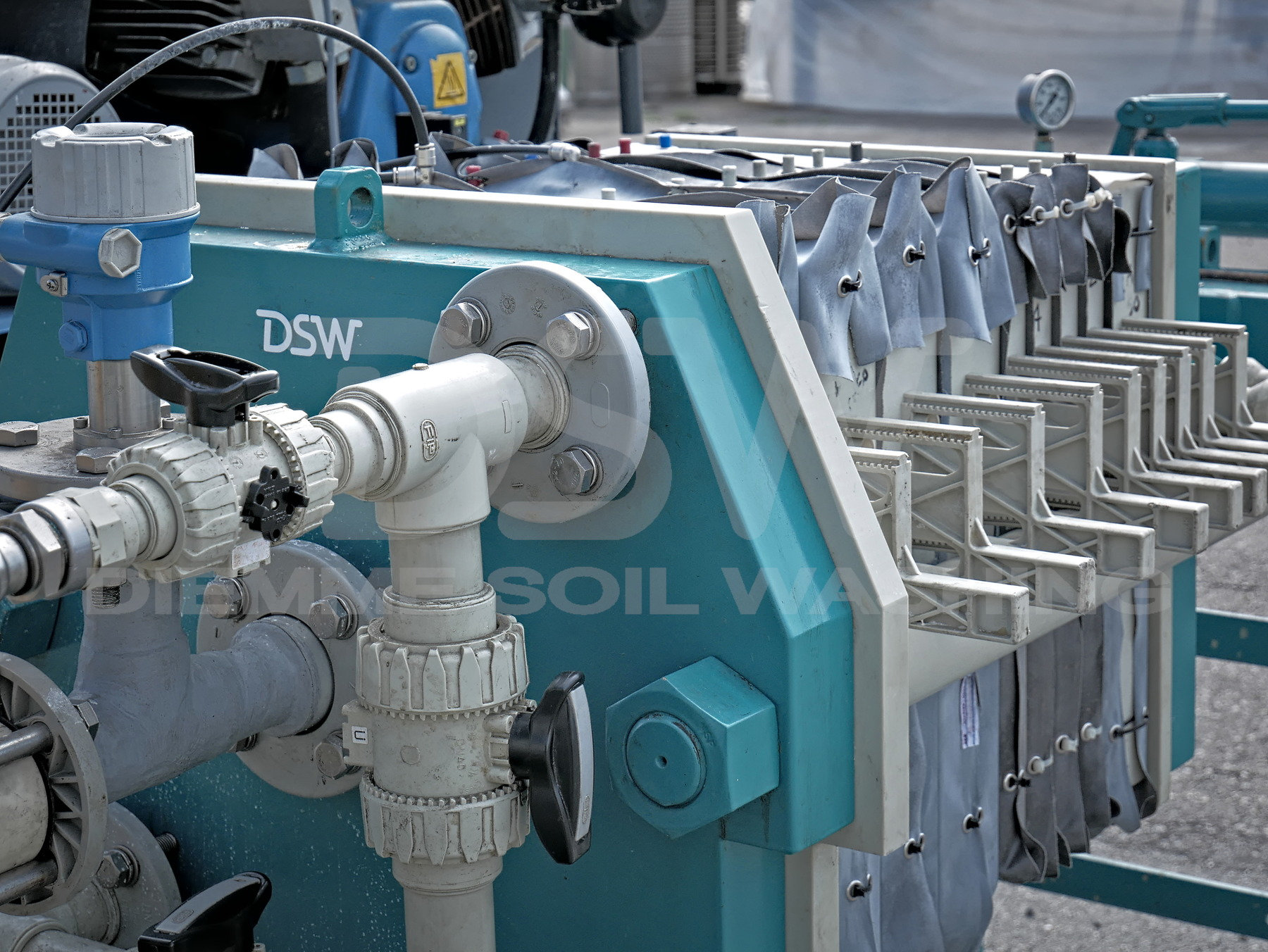

Filter Press MPS – Manual Filter Press

DIEMME SOIL WASHING with a tradition of group and highly qualified personnel in the field of solid-liquid separation almost secular, produces Filter Presses for various industrial sectors, with customized solutions for the specific needs of its customers.

The wide range of machines, the versatility given by the different combinations of plate sizes, the possibility of using fixed volume or variable volume chambers and side beam or upper beam frames with a hydraulic closing system in push or pull type, make DIEMME SOIL WASHING the ideal partner to face any requirement in the field of solid – liquid separation.

The Filter Presses designed and manufactured by DIEMME SOIL WASHING differ in the degree of automation that can be obtained, from manual to semi-automatic up to fully automatic.

The MPS model is available with a plate size from 500×500 mm and is mainly characterized by having a frame with manual or motorized hydraulic closing control unit and the manual movement of the plates during the opening phase. Available with fixed volume concamerated chamber plate or variable volume membrane plate pack or with plates and frames. The filtration phase can be completely automated and is suitable for complex processes with high added value.

Filter cloth kit specifically designed for the type of product to be filtered. Plates and frames with filter cardboard.

Given the manual nature of the plate pack opening and panel unloading operations, it is particularly suitable for small productions, even special ones or in cases of high flow rate and long lasting filtrations.

The filter press, according to the specific needs of the process, can be equipped with:

- Automatic end of filtration device

- Quality control of the filtrate

- Central collector expulsion at the end of the cycle with air or water and air

- Automatic depressurization of the filter press at the end of the cycle

- Washing of the panel in co-current or counter-current

- Panel drying with air or gas blowing before unloading

- Control of the weight of the panel unloaded with weighing cells

- Supervision and management of filtration parameters with customized software

- Remote assistance and remote connection module