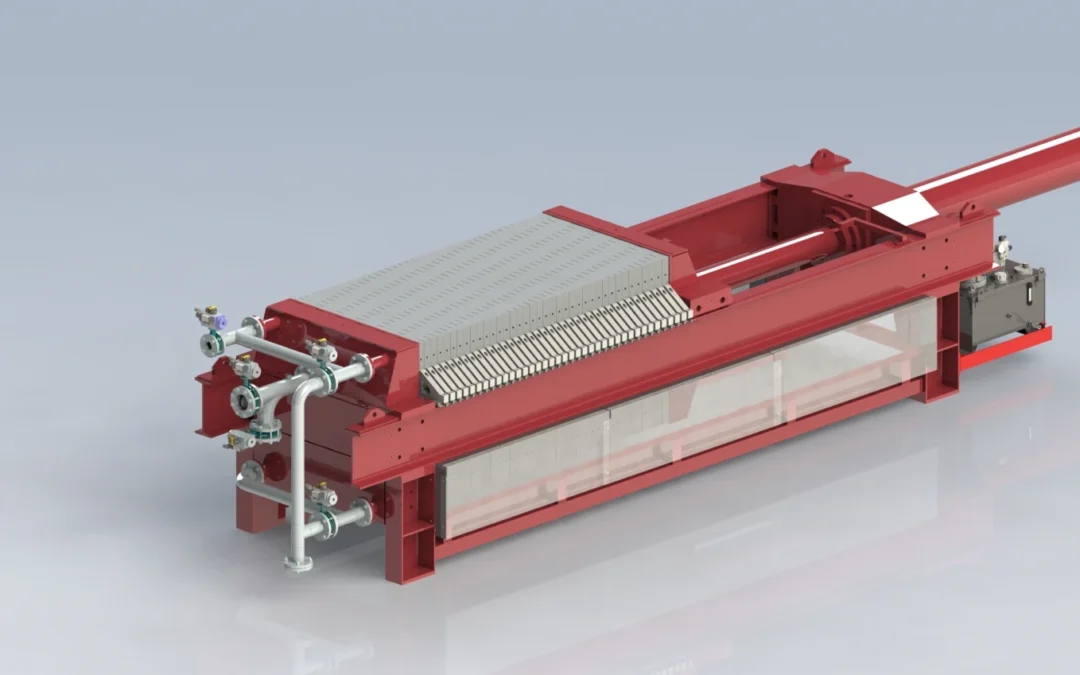

We are proud to present a new ambitious project: the construction of three filter presses of different sizes for the recovery of metals from spent catalysts and anode graphite from lithium battery recycling.

Each machine will be custom-designed and built by Diemme Soil Washing, featuring high-quality accessories made from corrosion-resistant noble materials and a work cycle specifically developed to meet the client’s needs.

The filter presses: 2 APS 800.63 units and 1 APS 800.41 unit are all mixed-pack machines with membrane plates, size: 800 x 800 mm. They will be equipped with all necessary accessories for cake washing and cake blowing. Emphasis is placed on safety, with protective systems including a photoelectric barrier on the operator side and fixed polycarbonate shielding on the opposite side of the machine.

This turnkey project includes on-site supervision during assembly and commissioning, full dry-run testing to ensure peak performance, and comprehensive training for involved personnel.

The filter presses designed and manufactured by Diemme Soil Washing have advanced technical features to improve operator safety, efficiency and durability of the equipment.

DIEMME Soil Washing will participate in the “DRC Mining Week 2025” fair.

We are excited to announce our participation in DRC Mining Week, a leading event for the African mining sector. This international conference and exhibition are designed to connect key players in the mining industry and provide a platform to showcase the latest...