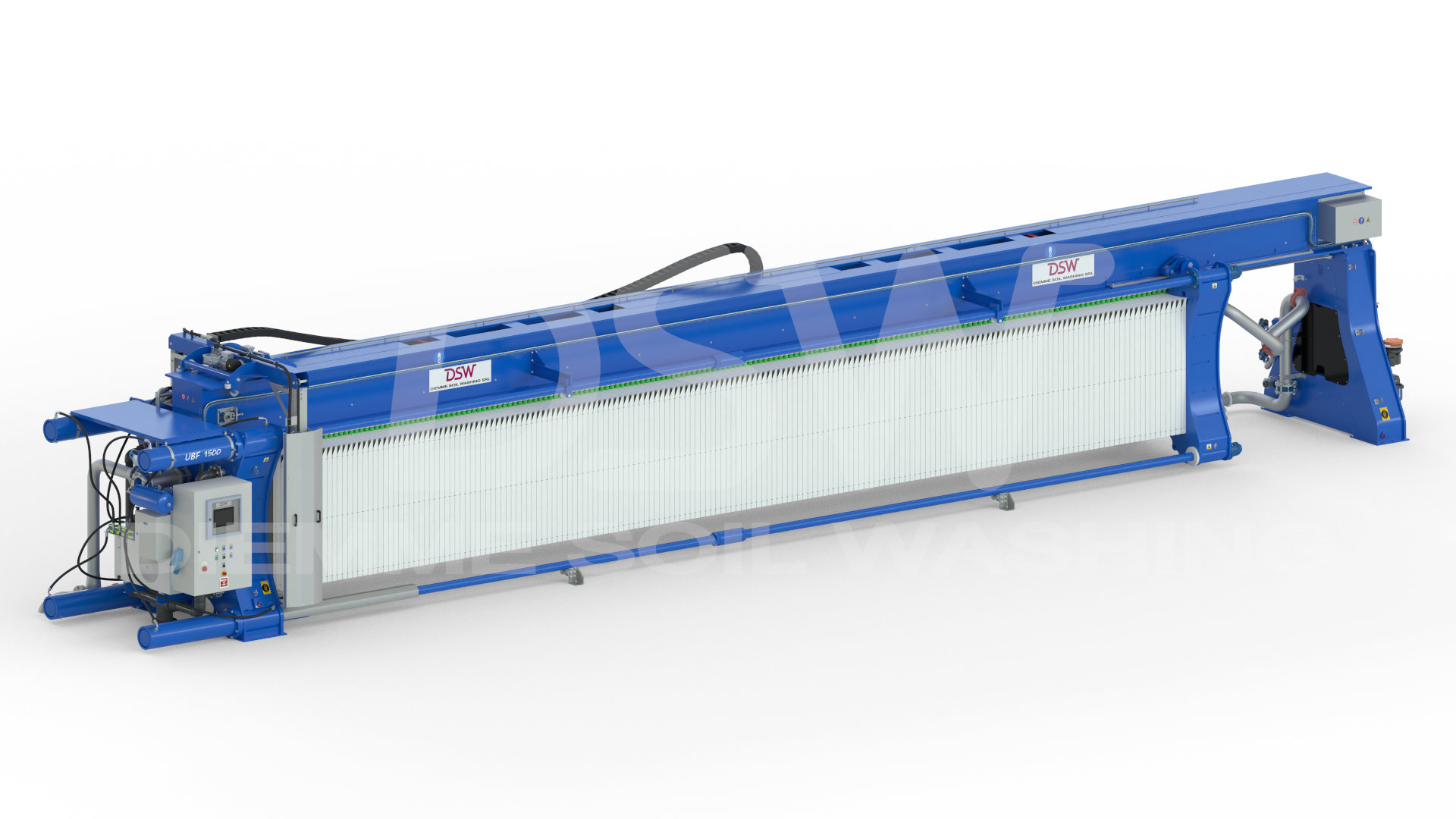

Filter Press UBF – Upper Beam Filter Press

Filter Press UBF – Upper Beam Filter Press

The Filter Press UBF model is characterized by the level of total automation together with a high beam frame pull-in closing system made by four jacks, it is available up to the plate size 2500×2500 mm.

The UBF model has the advantage of being a completely accessible machine, both laterally and at the top for easy management and maintainability of the moving and wear parts. It is characterized by extreme versatility and speed in the unloading phases. The plate movement sequence is automatic and managed by an inverter with the possibility of adjusting the plate shifting times.

Also available in the version with simultaneous opening of multiple packs of plates, it can also be equipped with a plate vibration device, to improve the discharge of the cake.

Available with fixed volume concamerated chamber plates and variable volume membrane plates in different configurations: full membrane, chamber and membrane mixed pack, interchangeable membrane and membrane block, central or angular feeding hole according to the different needs of the product to be filtered.

Depending on the filtration cycle required, the Filter Press can be equipped with piping and instrumentation to increase the level of automation of the production process in which the Filter Press must be inserted.

- Automatic end of filtration device

- Quality control of the filtrate

- Central collector expulsion at the end of the cycle with air or water and air

- Automatic depressurization of the filter press at the end of the cycle

- Washing of the panel in co-current or counter-current

- Panel drying with air or gas blowing before unloading

- Control of the weight of the panel/cake unloaded with weighing cells

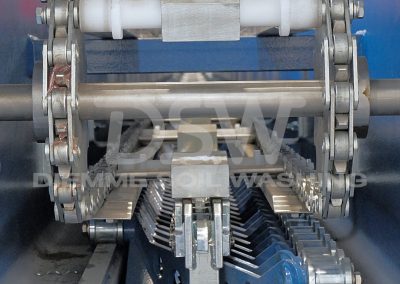

- Automatic high pressure type cloth washing system

- Automatic rain type cloth washing system

- Supervision and management of filtration parameters with customized software

- Remote assistance and remote connection module